Vaccine Storage and Handling - ppt download

Price: $ 59.00

4.8(212)

Disclosure Statements Neither the planners of this session nor I have any financial relationship with pharmaceutical companies, biomedical device manufacturers, or corporations whose products and services are related to the vaccines we discuss. There is no commercial support being received for this event. The mention of specific brands of vaccines in this presentation is for the purpose of providing education and does not constitute endorsement. The GA Immunization Office utilizes ACIP recommendations as the basis for this presentation and for our guidelines, policies, and recommendations. For certain vaccines this may represent a slight departure from or off-label use of the vaccine package insert guidelines. [Presenter is required to read this information to the audience before the program begins.] Neither the planners of this session nor I have any financial relationship with pharmaceutical companies, biomedical device manufacturers, or corporations whose products and services are related to the vaccines we discuss. There is no commercial support being received for this event. The mention of specific brands of vaccines in this presentation is for the purpose of providing education and does not constitute endorsement. The GA Immunization Office utilizes ACIP recommendations as the basis for this presentation and for our guidelines, policies, and recommendations. For certain vaccines this may represent a slight departure from or off-label use of the vaccine package insert guidelines..

Presentation to: Presented by: Date:.

To obtain nursing contact hours for this session, you must be present for the entire hour and complete an evaluation. Contact hours for this session only are available from 12/17/2013 until 8/31/2015. To obtain nursing contact hours for this session, you must be present for the entire hour and complete an evaluation. Contact hours for this session only are available for two (2) years from the date of implementation..

State three roles of the primary and alternate vaccine coordinators. List the proper storage equipment used for vaccine storage and handling monitoring. Identify the recommended thermometers used for vaccine storage and handling. List measures to prevent vaccine storage and handling mishaps. Discuss the components of routine and emergency plans for vaccine storage and handling. Locate resources relevant to current immunization practices. Presenter to review objectives and goals for presentation based on content outline..

Proper vaccine storage and handling practices play a very important part in preventing and eradicating vaccine-preventable diseases. Failure to adhere to required protocols for storage and handling can reduce vaccine potency, resulting in inadequate immune response in the recipients and poor protection against disease. Vaccine quality is a shared responsibility of everyone, from the time vaccine is manufactured until it is administered..

-Effectively trained personnel. -Appropriate transportation and storage equipment. -Efficient management procedures. Vaccines must be stored appropriately from the time they are manufactured until the time they are administered to a patient. Excessive heat or cold can reduce vaccine potency, increasing the risk that recipients will not be protected against vaccine-preventable diseases. A temperature-controlled environment used to maintain and distribute vaccines in optimal condition is called the vaccine cold chain. The vaccine cold chain relies on three main elements: Effectively trained personnel; Appropriate transportation and storage equipment, and; Efficient management procedures. All three elements must stay consistent to ensure vaccines are transported and stored appropriately. The vaccine cold chain begins with the cold storage unit at the vaccine manufacturing plant, extends through the transport of vaccine to the distributor, then delivery to the provider, and ends with the administration of the vaccine to the patient. Appropriate storage temperatures must be maintained at every link in the chain. Vaccine should always be transported in a refrigerated or frozen state. Refer to manufacturer protocols for each vaccine. Transport should include use of an insulated container or refrigerated truck. Appropriate temperatures are: Refrigerator between 35°F and 46°F [2°C and 8°C] Freezer between -58°F and +5°F [-50°C and -15°C].

Excessive heat or cold exposure can damage vaccines. Each time vaccines are exposed to excessive heat or cold, reduced potency increases. Inappropriate storage conditions can be costly. Vaccines are very expensive. Eventually, if the vaccine cold chain is not properly maintained, all potency will be lost, and the vaccines become useless. While exposure to both warm and cold temperatures can affect the potency of refrigerated vaccines, a single exposure to freezing temperatures will destroy some refrigerated vaccines. HepB and DTaP/DT/Tdap/Td vaccines are especially sensitive to freezing temperatures. That is why it is important to regularly monitor the temperature of your vaccines and take immediate corrective action when a storage unit temperature reading is outside the recommended range (temperature excursion). Vaccine Appearance after Exposure to Inappropriate Storage Conditions. Some vaccines may show physical evidence that potency has been reduced when exposed to inappropriate storage conditions. This may appear as clumping in the solution that does not go away when the vial is shaken. Other vaccines may look perfectly normal when exposed to inappropriate storage conditions. For example, inactivated vaccines exposed to freezing temperatures (i.e., 32°F [0°C] or colder) may not appear frozen and give no indication of reduced or lost potency. Therefore, visual inspection of vaccines must be considered unreliable when assuring vaccine was stored under appropriate conditions. In the General Recommendations on Immunization, the Advisory Committee on Immunization Practices (ACIP) recommends vaccine exposed to inappropriate temperatures that is inadvertently administered generally should be repeated. 4 Providers should contact their state/local health department immunization program, vaccine manufacturer(s), or both for guidance. Recalling patients to repeat vaccine doses should be considered. Vaccine recalls due to inappropriate storage can mean extra doses for patients, increased costs for providers, and damage to public confidence in vaccines. They can also be a liability for a provider’s practice. Patients who refuse revaccination can remain unprotected from serious, vaccine-preventable diseases. The costs associated with loss and replacement vaccines, and resources necessary to conduct a recall of patients, can be significant..

Store vaccines in appropriate type of refrigerator. Store vaccines in appropriate place in the refrigerator. Check temperatures and document temperatures. Now lets look at some tips for protecting our vaccines. The handout Temperature TIPS for Vaccine Storage summarizes the general principles discussed in this guidance..

Check expiration dates & rotate stock. Have routine and emergency vaccine handling plan. Take other preventive measures..

Designate a back-up person. Train all office staff working with vaccines. #1: Assign Responsibility for Handling Vaccine: Each facility should designate one staff member to be the primary vaccine coordinator. This person will be responsible for ensuring that all vaccines are stored and handled correctly. Vaccine storage and handling responsibilities include but are not limited to the following tasks: Each facility should assign one person primary responsibility for ensuring that vaccines are carefully handled in a safe, documented manner. Since no one works every single day, a back-up person should also be designated. All office staff working with vaccines should be familiar with storage and handling guidelines. Even the receptionist or temporary staff should know what to do with a shipment of Varicella or MMRV if it’s delivered and no one else is present..

Reading and documenting storage unit minimum/maximum temperatures. Downloading and reviewing stored temperature monitoring data at least weekly. Inspecting storage unit(s) daily. Coordinator Responsibility. Ordering vaccines. Overseeing proper receipt and storage of vaccine shipments. Organizing vaccines within the storage unit(s) Reading and documenting storage unit temperatures..

Maintaining storage equipment and records, including Vaccines for Children (VFC) program documentation in participating facilities. Ensuring that designated staff is adequately trained. Rotating stock. Responding to temperature excursions. Overseeing proper vaccine transport. Maintaining vaccine storage and handling documentation, including temperature excursion responses..

Each office should also designate at least one alternate vaccine coordinator who can assume these same responsibilities in the absence of the primary vaccine coordinator. The primary and alternate vaccine coordinators should be fully trained regarding routine and emergency policies and procedures related to vaccine shipments, storage, handling, transport, and inventory management..

Staff who handle and administer vaccines should receive comprehensive training regarding storage and handling policies and procedures. This training should be integrated into new staff orientation. Other Staff. All staff members who handle or administer vaccines should be familiar with the storage and handling policies and procedures at their facility. This includes not only those who administer vaccines, but also anyone who delivers or accepts shipments or who may have access to the unit(s) where vaccines are stored. Training. Staff who handle and administer vaccines should receive comprehensive training regarding storage and handling policies and procedures. This training should be integrated into new staff orientation. In addition, training should occur whenever recommendations are updated and when new vaccines are added to the facility’s inventory to maintain staff competency. Accountability checks should be put in place to ensure policies and procedures are followed..

While CDC does not recommend specific brands of vaccine storage units, CDC does provide guidance on types of storage units that offer greater assurance of proper temperatures for vaccine storage based on equipment testing by the National Institute of Standards and Technology (NIST). Purchasing new vaccine storage equipment may require planning and existing equipment may need to be used for a certain amount of time until new equipment can be purchased. In this situation, CDC recommends using a combination refrigerator/freezer unit for refrigerated vaccine only. A separate stand-alone freezer should be used to store frozen vaccines..

Have a calibrated thermometer inside each storage unit. Reliably maintain the appropriate vaccine storage temperatures year-round. Dedicated to the storage of vaccines. Food and beverages should NOT be stored in a vaccine storage unit. The refrigerator and freezer units must: Have enough room to store the year’s largest inventory without crowding; Have enough room to store water bottles (in the refrigerator) and frozen coolant packs (in the freezer) to stabilize the temperatures and minimize temperature excursions that can impact vaccine potency. The addition of water bottles in the refrigerator (not coolant packs) reduces the risk of freezing due to the tremendous latent heat released from water prior to freezing; Have a calibrated thermometer inside each storage unit; Reliably maintain the appropriate vaccine storage temperatures year-round; Be dedicated to the storage of vaccines. Food and beverages should NOT be stored in a vaccine storage unit because this practice results in frequent opening of the door and destabilization of the temperature..

While CDC does not recommend specific brands of vaccine storage units, CDC does provide guidance on types of storage units that offer greater assurance of proper temperatures for vaccine storage based on equipment testing by the National Institute of Standards and Technology (NIST). CDC recommends stand-alone units, meaning self-contained units that only refrigerate or freeze, and are suitable for vaccine storage. These units can vary in size, from compact, under-the-counter style to large, stand-alone, pharmaceutical grade units. The refrigerator and freezer units must: Have enough room to store the year’s largest inventory without crowding; Have enough room to store water bottles (in the refrigerator) and frozen coolant packs (in the freezer) to stabilize the temperatures and minimize temperature excursions that can impact vaccine potency. The addition of water bottles in the refrigerator (not coolant packs) reduces the risk of freezing due to the tremendous latent heat released from water prior to freezing; Have a calibrated thermometer inside each storage unit; Reliably maintain the appropriate vaccine storage temperatures year-round; Be dedicated to the storage of vaccines. Food and beverages should NOT be stored in a vaccine storage unit because this practice results in frequent opening of the door and destabilization of the temperature. -50° F and – 15° F ( -58° C and + 5 ° C).

Guidelines – 4 to 6 inches of clearance around outside of unit (Check manufacturer manual to verify minimum spacing) Well-ventilated room for maintaining ambient conditions within manufacturer specifications. Startup. Remove any vegetable/ dairy bins (not suitable for vaccine storage) Place filled water bottles in areas where vaccine storage is prohibited..

You can help stabilize the temperature in the freezer by keeping frozen coolant packs inside. Store the frozen coolant packs along the walls, back, and bottom of the freezer and inside the racks of the freezer door. Frozen coolant packs in the freezer door and water containers in the refrigerator door should be placed securely so they cannot dislodge and prevent unit doors from closing. In addition, caution must be taken to avoid weighing down a door so much that the seal is compromised when the door is closed. Not only will water bottles and frozen coolant packs help maintain even temperatures in the storage unit with frequent opening and closing of the doors, they will also help to keep the temperatures stable in the event of a power failure..

Daily Maintenance. Read and document the internal temperature. Check that each unit door is closed. Monthly Maintenance. Clean the coils and motor. Clean the refrigerator and freezer unit. Check the door seal. Periodic Maintenance. Clean the drain pan. General Principles. The most important action to take if vaccine storage units are not working properly is to protect the vaccine supply. The most important action to take if vaccine storage units are not working properly is to protect the vaccine supply. If the problem is short term (usually 2 hours or less) and depending on ambient room temperature, the temperatures in the storage units can probably be maintained with water containers in the refrigerator, with frozen coolant packs in the freezer, and by keeping the unit doors closed. If there is an extended period of time before the situation can be corrected and there are no other storage units available on site, the vaccines should be moved to the back-up storage facility using the guidelines in the Emergency Vaccine Retrieval and Storage Plan (see the Storage and Handling Plans section). After this is accomplished, attempt to find the cause of the problem and correct it (see the Storage Troubleshooting section). Do NOT allow vaccines to remain in nonfunctioning units for an extended period of time while you attempt to resolve a problem..

For measuring vaccine storage unit temperatures, CDC recommends using only calibrated thermometers with a Certificate of Traceability and Calibration Testing. This certificate informs user of a thermometer’s level of accuracy compared to a recognized standard. Thermometers are a critical part of good storage and handling practice. A storage unit is only as effective as the temperature monitoring system inside. Accurate temperature history that reflects actual vaccine temperatures is imperative to effective vaccine management. Every freezer and refrigerator unit used to store vaccine should have a calibrated thermometer. Thermometer calibration must be tested annually or according to the manufacturer’s recommendation by a laboratory with accreditation from an International Laboratory Accreditation Cooperation (ILAC) Mutual Recognition Arrangement (MRA) signatory body. When choosing a thermometer, look for high accuracy, +/-1°F (+/-.5°C). This information should be contained in the Certificate of Traceability and Calibration Testing (also known as a Report of Calibration). Example of Thermometer Certificate of Traceability and Calibration Testing. All thermometers experience drift over time that affects their accuracy. When the Certificate of Traceability and Calibration Testing (also known as a Report of Calibration) expires, CDC recommends one of the following: Have the accuracy of your thermometer tested by an accredited laboratory. Purchase a new thermometer with a Certificate of Traceability and Calibration Testing (also known as a Report of Calibration) Contact your immunization program for resources on checking the accuracy of your thermometer..

Thermometers. Thermometer Characteristics. Continuous monitoring with active display. Alarm for out-of-range temperatures. Reset button if using data logger with min/max display. Shows current temperature as well as min/max temperatures. Be within +/- .5° C accuracy (+/- 1° F) Low Battery Indicator. To ensure that refrigerators and freezers are maintaining the appropriate temperatures for vaccine storage, each unit should have a calibrated thermometer. Temperatures for each unit should be read and documented a minimum of twice each workday, including recording the minimum and maximum temperatures once each day. The temperature data, regardless of whether using paper or downloaded files, should be kept in a safe, retrievable place for at least 3 years. Several types of thermometers can be used to monitor the temperatures within vaccine storage units. Based on studies of thermometers conducted by NIST in 2009, CDC recommends using a digital thermometer with a detachable probe that is kept in a glycol-filled bottle. A detachable probe facilitates downloading temperature data without removing the probe from the storage unit. NIST studies demonstrated that these probes in glycol-filled bottles can more closely approximate the vaccine vial temperature when placed in the same area where the vaccine is stored.1..

CDC recommends using temperature monitoring devices that allow for the main device to remain outside of the storage unit as this allows for reading temperatures without opening the unit door. The main device is attached to the internal temperature probe through a narrow cable (usually 1 to 3 meters long) with the probe placed in glycol and positioned near the vaccine. To download data, the main unit can be easily disconnected from the cable, leaving the probe inside the storage unit. CDC recommends having a back-up temperature probe for each vaccine storage unit, in the event that something happens to the primary temperature probe or if the primary probe needs to be sent to a laboratory for calibration. The back-up probe should have the same set up as the primary set up (i.e., temperature probe in glycol). In addition, CDC recommends that the back-up probe have a different calibration schedule than the primary probe so that your back-up is available when the primary probe is sent for calibration. Probe in glycol bottle inside unit attached to main monitor. Probe in glycol placed in proximity to vaccines. Main monitor outside storage unit..

CDC recommends using digital data loggers for continuous temperature monitoring in vaccine storage units. These miniature electronic devices may be programmed to record temperatures at intervals throughout the day, with the frequency of reading set by the user. Digital data logger thermometers are capable of recording hundreds or even thousands of individual temperature readings. Digital data loggers come in many shapes, sizes and styles and are typically battery operated..

Current temp., as well as min/max temps. Reset button. Low battery indicator. Accuracy of +/-1° F (0.5° C) Memory storage of at least 4000 readings. User programmable logging interval (reading rate) Digital data logger thermometers used for vaccine storage are accompanied by special software that is installed on a computer. This software allows the user to set the frequency of the temperature readings, download data from the device, and calculate temperature averages, minimums, and maximums. To review the temperature history, the user must download data from the digital data logger thermometer on a regular basis. Digital data logger thermometers have a variety of features in addition to their basic recording function. All contain a probe that is used to detect temperature readings. As stated previously, CDC recommends the use of glycol-encased probes, rather than air probes, because they provide a more accurate reading of actual vaccine temperature..

Fluid filled biosafe liquid thermometers. Bi-metal stem thermometers. Food thermometers and household mercury thermometers. Chart recorders. Infrared thermometers. Thermometers not calibrated. These thermometers can have significant limitations in vaccine temperature monitoring. They can be difficult to read and only indicate the temperature at the precise time they are read. Therefore, temperature fluctuations outside the recommended range may not be detected. Chart recorders are more difficult to read than digital thermometers because they require interpretation of the temperature graph. In addition, the chart paper must be changed when it is filled and there is insufficient room to record readings. Failure to change the chart paper will result in unusable temperature data. If a facility does not have access to a computer, however this paper based logger may be the only other choice for continuous temperature monitoring. A NIST review of IR thermometers demonstrated that these devices are not reliable or accurate for assessment of vaccine storage temperatures. Generally, thermometers obtained in hardware and appliance stores are not calibrated instruments and are designed to monitor temperatures for domestic food storage. These thermometers are not accurate enough and can pose a significant risk to losing expensive vaccine..

Placement within the unit is just as important as thermometer selection. The thermometer should be in proximity to the vaccines being stored. Thermometers should NOT be: Placed in the doors. Near or against the walls. Close to vents. On the floor of the unit. A thermometer can inadvertently be displaced during a busy workday. Ensure appropriate placement of the thermometer in each unit with daily inspection of each storage unit. Proper placement is very important since it helps the provider to most accurately identify the actual vaccine vial temperature and to take immediate corrective action if necessary..

Only the primary or alternate vaccine coordinator should adjust the temperature of a vaccine storage unit. A warning sign should be posted on the storage unit that says, Do not adjust refrigerator (or freezer) temperature controls. Limiting access to the thermostat reduces the risk that the temperatures will be adjusted inappropriately. In some situations, the thermostat may need to be reset in summer and winter, depending on the ambient room temperature. If the thermostat requires adjustment, alert the vaccine coordinator or immediate supervisor. Use caution in adjusting a thermostat. Normal defrost cycles and busy workdays can lead to slight temperature variations that are not necessarily indicative of inappropriate vaccine temperatures. It may take 2 to 7 days to stabilize the temperature between 35°F and 46°F (2°C and 8°C) in a newly installed or repaired refrigerator. Likewise, it may take 2 to 3 days to stabilize the temperature between -58°F and +5°F (-50°C and -15°C) in a newly installed or repaired freezer. Allow one week of twice daily refrigerator and freezer temperature recordings, including minimum/maximum temperatures daily (preferably in the morning) to make sure temperatures are within the appropriate ranges before using the units to store vaccines..

Temperatures can vary in a vaccine storage unit based on the contents, how often the door is opened, and power interruptions. The only way to be sure the temperature in a storage unit has remained within the appropriate range is to frequently read and document the temperature using a calibrated thermometer. Stabilizing the Temperatures with Water Bottles and Frozen Coolant Packs. You can help stabilize the temperature in the refrigerator by keeping at least two or three large containers of water inside. Store water bottles labeled Do NOT drink against the inside walls and in the door racks. You can help stabilize the temperature in the freezer by keeping frozen coolant packs inside. Opening the Door. Limit the number of times the vaccine storage unit door is opened and avoid letting the door stand open unnecessarily. Not only does this affect the temperature in the unit, it also exposes the vaccines to light, which can reduce the potency of some vaccines (see CDC’s Vaccine Storage and Handling Guide for vaccine-specific recommendations). Routinely check the refrigerator and freezer doors throughout the day and at the end of each workday to ensure they are tightly closed. Deli, Fruit, and Vegetable Drawers. Remove any deli, fruit, and vegetable drawers from the refrigerator. Removing the drawers not only provides extra space for storing containers of water, but it also removes the temptation to use the drawers for storage of food, beverages, or vaccines..

Best Practices: Post temperature log on storage unit. Read thermometer in both storage units twice daily (morning/end of work day) Read min/max temperatures in both units a minimum of once each work day. Document readings for both units on temperature log. Record times of reading and staff initial who took reading. Download and review stored continuous monitoring data at least weekly. CDC recommends the routine vaccine storage and handling plan include reading and documenting storage unit temperatures a minimum of twice each workday, as well as the minimum/maximum temperatures daily (preferably in the morning). This best practice recommendation can prevent inadvertent loss of vaccine and the potential need for revaccination by assuring that temperature excursions are identified quickly so that immediate corrective action can be taken. This also provides an opportunity to visually inspect the storage unit, reorganize any vaccines that are inadvertently misplaced, and remove any expired vaccines. CDC recommends the use of a continuous monitoring device/digital data logger to record and store temperature information at frequent programmable intervals for 24-hour temperature monitoring. CDC’s interim recommendation is to set the digital data logger to measure every 15 minutes. If you wish to set the data logger to measure the temperature more frequently or if the manufacturer recommends a more frequent setting, that is acceptable. CDC is currently working with NIST to evaluate the most efficient and effective settings for digital data logger temperature measurements. Stored temperature monitoring data should be downloaded and reviewed at least weekly by providers, both to ensure the timely review of the data and the appropriate response to issues. When the data is downloaded, the data logger should be reset so there is sufficient memory available. The downloaded information should be kept for a minimum of 3 years or according to individual state record retention requirements..

JM :00. Best Practices: Best practices include: Post a temperature log or other appropriate recording document on each storage unit door. Read the thermometers in both the refrigerator and freezer units a minimum of twice each workday, at least once in the morning and once before leaving at the end of the workday. Read the minimum/maximum temperatures in both the refrigerator and freezer units a minimum of once each workday, preferably in the morning. Document the readings in both the refrigerator and freezer units on temperature logs each time the thermometers are read. Record the times of the thermometer readings and the initials of the person who took the readings. If a temperature reading is missed, the log entry should remain blank. Download and review stored continuous monitoring data at least weekly. If other staff are monitoring and documenting the temperatures, the primary vaccine coordinator should review the temperature recording data weekly to ensure appropriate temperature documentation. If the vaccine coordinator is the person monitoring and documenting the temperatures, the alternate vaccine coordinator should review the data weekly..

Avoiding Storage and Handling Mishaps.

Examine shipments on arrival. Examine container and contents for damage. Cross-check contents with the packing slip. Check the shipment date. Record shipment on an inventory log. #2: Check Vaccine Shipments. Your responsibility for proper vaccine storage and handling begins the moment the vaccine arrives. Vaccine shipments should be examined on arrival. Examine the shipping container and its contents for any evidence of damage during transport. Cross- check the contents with the packing slip to be sure they match. Check the shipment date to determine how long the package was in transit to you. If the interval between shipment from the supplier and arrival of the product at its destination was excessive, particularly if the ice packs or dry ice has melted, it could mean the vaccine has been exposed to excessive heat or cold that might alter its integrity. Finally, each shipment should be recorded on an inventory log. This log should include the name of each vaccine; the number of doses for each vaccine received; the date it was received; the condition of the vaccines upon arrival; the name of the vaccine manufacturers; the lot numbers; and the expiration dates for each vaccine. If there are any discrepancies with the packing slip or concerns about the vaccine shipment, store the vaccine under proper conditions (do not automatically discard) and mark Do Not Use until the integrity of the vaccine is determined. You will then need to contact the state immunization office and manufacturer for further guidance..

A best practice is to place vaccine in the central area of the storage space and keep vaccines in their original packaging inside storage trays positioned 2 to 3 inches away from storage unit walls. Vaccine Spacing-allow for cold air circulation. Vaccine Packaging-similar packaging should be stored in different locations. Freezers. Vaccines should be stored away from the walls and vents in the part of the freezer best able to maintain the required temperature range (between -58°F and +5°F (-50°C and -15°C). Vaccines should not be stored in the freezer door. The temperature in the door is not stable and differs from that inside the unit. Frozen coolant packs can be stored in the freezer door. Refrigerators. In the refrigerator, vaccines should be placed away from the walls, floor, and vents in the part of the unit best able to maintain the required temperature between 35°F and 46°F (2°C and 8°C). Vaccines should not be stored in the deli, fruit, and vegetable drawers, in the door, or on the floor of the unit..

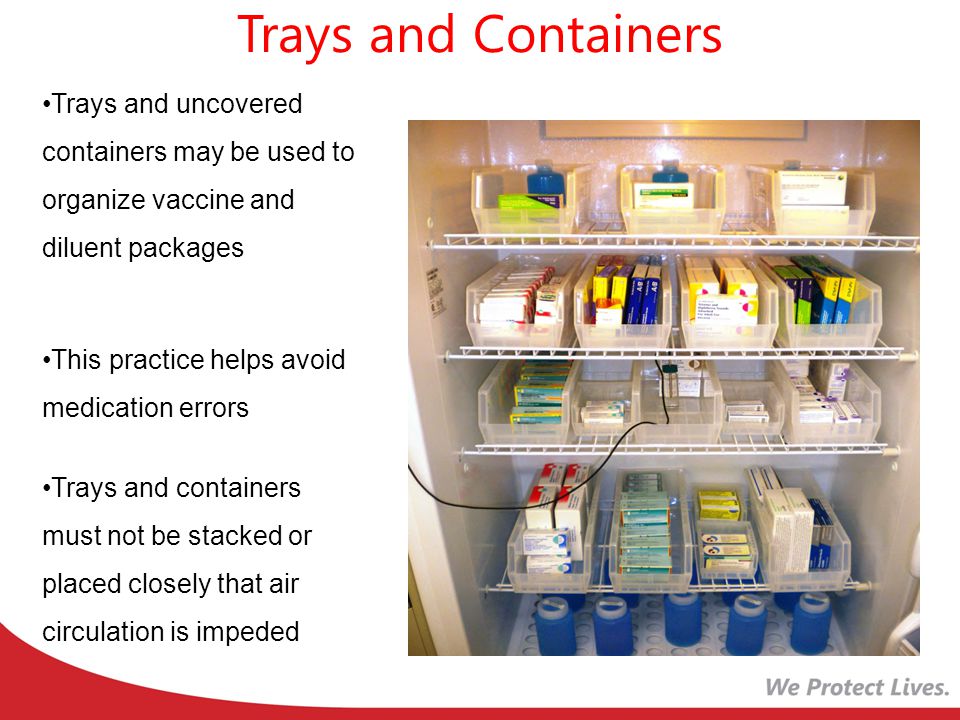

The location of each specific vaccine type inside the storage unit should be clearly labeled. This can be accomplished by attaching labels directly to the shelves on which the vaccines are placed or by labeling containers in which packages of the same vaccine type are placed. Storing each vaccine type in its own specifically-labeled section of the refrigerator or freezer helps decrease the chance that someone will inadvertently administer the wrong vaccine. Label pediatric and adult versions of the same vaccine clearly to avoid confusion (see CDC’s Vaccine Labels for Storage Unit). In addition to labeling the location of vaccines, mark each opened multidose vial with the date it was first opened. Mark reconstituted vaccine with the date and time it was reconstituted. Dating these vials is important for two reasons. First, some vaccines expire within a certain time after opening or after reconstitution (beyond use date [BUD]). The BUD varies among vaccines (see CDC’s Vaccine Storage and Handling Guide for specific vaccine product information). This may not correspond to the expiration date printed on the vial by the manufacturer. For example, multidose vials of MPSV4 should be discarded if not used within 35 days after reconstitution, even if the expiration date printed on the vial by the manufacturer has not passed. Second, dating opened or reconstituted vials helps manage vaccine inventory by identifying vials that should be used first. Attach labels directly to the shelves on which the vaccines are placed, or label trays or containers according to the vaccines they contain..

This practice helps avoid medication errors. Trays and containers must not be stacked or placed closely that air circulation is impeded. Storage Containers. Vaccine and Diluent Packages. To avoid confusion, vaccine and diluent packages should be stored together by type and arranged in rows. Vaccines and diluents should be stacked according to expiration dates. Vaccines and diluents with the shortest expiration dates should be closer to the front of the storage unit for easy access. Store all opened and unopened vaccines and diluents in their original packaging inside the appropriate storage unit so that the contents and expiration dates are easily identifiable. Storing loose vaccine and diluent vials outside of their packaging is not recommended. This practice makes managing inventory and tracking expiration dates more difficult, increases administration errors when staff is confused about vials, and exposes the vaccines to light. Some diluents can be stored at room temperature (if they do not contain any antigen), separate from their corresponding vaccines. In this case, always assure that the correct diluent is used with the correct vaccine. Trays and Containers. Trays and uncovered containers may be used to organize vaccine and diluent packages. Each tray or uncovered container should only contain vaccine or diluent of the same type. If other medications and biologic products must be stored in the vaccine storage unit, they must not be stored on the trays or in the containers with vaccine or diluent. This practice helps avoid medication errors. Clearly label the tray or container with the name of the vaccine or diluent, and place packages of that type on the tray or in the container inside the appropriate storage unit. Trays and containers must not be stacked or placed so closely together that air circulation inside the storage unit is impeded..

Check expiration date/rearrange the placement of vaccine and diluent in storage unit. Short-dated placed in front. Expired vaccines and diluents should NEVER be administered. Remove expired vaccines/diluents from unit. Keep Vaccines Organized. Check and rotate vaccine stock weekly so that vaccines with the shortest expiration dates are in the front to be used first. If the expiration date on the vial is identified only as month and year, the vaccine does not expire until the LAST day of the month indicated on the vial. Expired vaccine - even if only one day after the expiration date- should NEVER be administered. Promptly remove expired vaccine from the refrigerator or freezer and dispose of it appropriately. If the expired vaccine is VFC vaccine, you should contact the GA VFC program so that the expired vaccine can be accounted for. Also as you check your vaccine expiration dates, when you note that you have vaccine that will expire before you can use all of it ( 3 months), you need to call the GA VFC program and let us know so we can have time to move it elsewhere. In addition, the same person should be responsible for documenting all vaccine wastage and making sure spoiled or expired vaccine is returned to the state. Keep opened vials of vaccine in a tray, so that they are readily identifiable. Indicate on the label of each vaccine vial the date and time it was reconstituted or first opened. Influenza, pneumococcal polysaccharide, IPV, Td and tetanus toxoid are manufactured in multi-dose and single dose vials or syringes. If your clinic situation permits, open only one vial, or box, of a particular vaccine at a time to control vaccine usage and allow easier inventory control. We also recommend that all opened vaccine vials be kept in a tray in the refrigerator separate from other medications and biologics to avoid medication errors. To keep an accurate account of your inventory, keep your VFC vaccine stock separated from your privately purchased vaccine supply. Vaccine Stock Rotation. When new shipments arrive, vaccines should be unpacked immediately. The local practice vaccine coordinator should ensure that someone checks and rearranges the placement of vaccine and diluent supplies in the storage unit according to the expiration dates on a weekly basis and each time a vaccine shipment arrives. The vials and packages with the earliest expiration dates should be placed in front of other vials and packages of the same type of vaccine with later expiration dates. This practice avoids waste by ensuring that vaccines and diluents with the shortest expiration dates are easily accessible and will be used first, thereby limiting the amount of unused vaccine that has passed the expiration date. Expired vaccines and diluents should NEVER be administered. IMMEDIATELY remove expired vaccines and diluents from the storage unit(s) to avoid the risk of inadvertent use..

Providers must store vaccine separately in their refrigerator based on funding split totals printed on the packing slip received from McKesson. Funding splits are based on the provider’s profile submitted upon enrollment and annually during recertification. VFC. CHIP/317. PRIVATE..

The Georgia VFC Program has always discouraged borrowing of VFC vaccine. New program changes require corrective action for providers found borrowing VFC vaccine for non-eligible patients. NO BORROWING..

Avoid using power outlets with built-in circuit switches. Use a safety-lock plug or an outlet cover. Post a warning sign at the plug and on the refrigerator and freezer units. Label the fuses and circuit breakers to alert people not to turn off the power to the storage units. Consider installing a temperature alarm to alert staff to after-hours temperature excursions. Back-up generators. To keep a storage unit temperature within the appropriate range, the unit must be in good working condition, and it must have power at all times. To prevent problems with the power supply, take the following steps: Avoid using power outlets with built-in circuit switches (they have little red reset buttons), outlets that can be activated by a wall switch, or power strips. These can be tripped or switched off, resulting in loss of electricity to the storage unit. Use a safety-lock plug or an outlet cover to reduce the chance of a unit becoming inadvertently unplugged. Post a warning sign at the plug and on the refrigerator and freezer units alerting staff, janitors, electricians, or any workers not to unplug the units. Label the fuses and circuit breakers to alert people not to turn off the power to the storage units. These labels should include information concerning the immediate steps to take if power is interrupted. When the practice is located in a building owned by a third party and providers do not have access to the circuit breaker, ask the building manager to assist in labeling the appropriate circuit. Consider installing a temperature alarm to alert staff to after-hours temperature excursions, particularly if large vaccine inventories are maintained. Facilities storing large vaccine inventories should consider installing back-up generators that automatically provide power to the storage units to maintain the recommended storage temperatures in the event of power outages..

Avoid using power outlets with built-in circuit switches and outlets that can be activated by a wall switch. Safety-lock plug. Consider using outlet covers. Post warning signs and labels. Continuous-monitoring temperature alarm/notification systems. Back-up generators..

Vaccine manufacturers do not generally recommend or provide guidance for transport of vaccines. If vaccines must be transported during an emergency or to an off-site facility, it is critical that vaccine potency is protected by maintaining the vaccine cold chain at all times. If at all possible, have vaccines delivered directly to an off-site facility. The number of times vaccines are handled and transported should be kept to a minimum. Each transport increases the risk that vaccines will be exposed to inappropriate storage conditions. If you cannot ensure that the vaccines are transported under proper conditions to maintain the vaccine cold chain, then do NOT transport vaccines unless it is an emergency. If vaccines must be transported to an off-site facility, the amount of vaccines transported should be limited to the amount needed for that workday to avoid potential loss of expensive vaccines. Providers should contact manufacturer(s) and/or the state/local health department immunization program for guidance specific to their area..

Not placed in the trunk of the vehicle. Delivered directly to the facility. Promptly unpacked and placed into appropriate storage units upon arrival. The facility SOP should specify that the vaccines are: Attended at all times during transport; Not placed in the trunk of the vehicle; Delivered directly to the facility; Promptly unpacked and placed into appropriate storage units upon arrival (see Checking the Condition of a Shipment in the Vaccine Shipments section)..

When a multi-dose vial is used, FDA regulations require that it only be used in the facility where it was first opened. Only if absolutely necessary, a partially used vial may be transported to or from an off-site facility operated by the same provider, as long as the vaccine cold chain is properly maintained Varicella-containing vaccines may be transported at refrigerator temperature between 36°F and 46°F (2°C and 8°C) for up to 72 continuous hours prior to reconstitution (see Varicella-Containing Vaccines in CDC’s Vaccine Storage and Handling Guide). If varicella-containing vaccines must be transported at refrigerator temperature, follow these steps: 1. Place a calibrated thermometer (preferably with a biosafe glycol-encased thermometer probe) in the container used for transport as close as possible to the vaccines. 2. Record: a. The time the vaccines are removed from the storage unit and placed in the container; b. The temperature during transport; c. The time and temperature at the beginning and end of transport. 3. According to the vaccine manufacturer, immediately upon arrival at the alternate storage facility: a. Place the vaccines in the freezer between -58°F and +5°F (-50°C and -15°C) and label DO NOT USE. Any stand-alone freezer that reliably maintains a temperature between -58°F and +5°F (-50°C and -15°C) is acceptable for storage of varicella-containing vaccines. b. Document the time the vaccines are removed from the container and placed in the alternate storage unit. c. Note that this is considered a temperature excursion, so contact the manufacturer at for further guidance. 4. Do not discard vaccines without contacting the manufacturer and/or your immunization program for guidance. Use of dry ice is not recommended, even for temporary storage or emergency transport. Dry ice may subject varicella-containing vaccines to temperatures colder than -58°F (-50°C)..

The vaccine manufacturer does not recommend transporting varicella-containing vaccines (MMRV, VAR, HZV). If these vaccines must be transported (e.g., during an emergency), CDC recommends transport in a portable freezer unit that maintains the temperature between -58°F and +5°F (-50°C and -15°C). Do Not Use Dry Ice..

Varicella-containing vaccines may be transported at refrigerator temperature between 36°F and 46°F (2°C and 8°C) for up to 72 continuous hours prior to reconstitution. If varicella-containing vaccines must be transported at refrigerator temperature, follow these steps: Place calibrated thermometer in container. Record time vaccines and placed in container, temperature during transport, and time and temperature at the beginning and end of transport. Immediately, upon arrival at alternate storage facility, place vaccines in the freezer between -58°F and +5°F (-50°C and -15°C) and label DO NOT USE. Document time the vaccines are removed from the container and placed in alternate storage unit. Note that this is considered a temperature excursion, so contact the manufacturer for further guidance. Do not discard vaccines without contacting the manufacturer and/or your immunization program for guidance. Transporting Varicella-Containing Vaccines. The vaccine manufacturer does not recommend transporting varicella-containing vaccines (MMRV, VAR, HZV). If these vaccines must be transported (e.g., during an emergency), CDC recommends transport in a portable freezer unit that maintains the temperature between -58°F and +5°F (-50°C and -15°C). Portable freezers may be available for rent in some places. If varicella-containing vaccines must be transported and a portable freezer unit is not available, do NOT use dry ice. Varicella-containing vaccines may be transported at refrigerator temperature between 36°F and 46°F (2°C and 8°C) for up to 72 continuous hours prior to reconstitution (see Varicella-Containing Vaccines in CDC’s Vaccine Storage and Handling Guide). If varicella-containing vaccines must be transported at refrigerator temperature, follow these steps: 1. Place a calibrated thermometer (preferably with a biosafe glycol-encased thermometer probe) in the container used for transport as close as possible to the vaccines. 2. Record: a. The time the vaccines are removed from the storage unit and placed in the container; b. The temperature during transport; c. The time and temperature at the beginning and end of transport. 3. According to the vaccine manufacturer, immediately upon arrival at the alternate storage facility: a. Place the vaccines in the freezer between -58°F and +5°F (-50°C and -15°C) and label DO NOT USE. Any stand-alone freezer that reliably maintains a temperature between -58°F and +5°F (-50°C and -15°C) is acceptable for storage of varicella-containing vaccines. b. Document the time the vaccines are removed from the container and placed in the alternate storage unit. c. Note that this is considered a temperature excursion, so contact the manufacturer at for further guidance. 4. Do not discard vaccines without contacting the manufacturer and/or your immunization program for guidance. Use of dry ice is not recommended, even for temporary storage or emergency transport. Dry ice may subject varicella-containing vaccines to temperatures colder than -58°F (-50°C)..

Refrigerated/frozen coolant packs. CDC recommends transport with a portable refrigerator unit. If this type of unit is not available, a hard-sided insulated cooler with at least 2-inch walls may be used if it can maintain the recommended temperature range (between 35°F and 46°F [2°C and 8°C]). Packing Vaccines and Diluents for Transport. There are many variables to consider when transporting any vaccine (e.g., the time of year and ambient temperature, the amount of vaccine, the shipping container, etc.) Your immunization program may have specific guidance regarding vaccine transport, details on how to pack vaccine and diluent, and procedures for maintaining the vaccine cold chain based on these variables. Here is some general guidance. Refrigerated vaccines. ● Pack refrigerated vaccines before packing frozen vaccines as indicated here: CDC recommends transport with a portable refrigerator unit. If this type of unit is not available, a hard-sided insulated cooler with at least 2-inch walls may be used if it can maintain the recommended temperature range (between 35°F and 46°F [2°C and 8°C]). ● Place a layer (at least 2 inches) of conditioned coolant packs in the transport container first. Coolant packs that are frozen must be conditioned by leaving them at room temperature for 1 to 2 hours until the edges have defrosted and the packs look like they’ve been sweating. Frozen coolant packs that are not conditioned can freeze vaccine. Place an insulating barrier layer on top of the coolant packs, (e.g., bubble wrap or Styrofoam pellets). Place a calibrated thermometer (preferably with a biosafe glycol-encased thermometer probe) on top of the barrier next to the vaccines. Stack the vaccines on top of the barrier and thermometer, ensuring that the vaccines do not touch the coolant packs. Place another insulating barrier layer on top of the vaccines. Place another layer of conditioned coolant packs on top of the insulating barrier layer, ensuring there is no direct contact between the coolant packs and the vaccines. Place a final insulating barrier layer (at least 2 inches) on top of the coolant packs along with an inventory list of the vaccines in the container. Frozen vaccines. If frozen vaccines must be transported, CDC recommends transport with a portable freezer that maintains a temperature between -58°F and +5°F (-50°C and -15°C). Use the same packing layers as noted above. The coolant packs should be frozen. Do NOT use dry ice. Diluents. ● Diluents should be transported with their corresponding vaccines to ensure that there are always equal numbers of vaccine vials and diluent vials for reconstitution. NEVER transport any diluents at freezer temperature because the vials could crack, or in some cases, the diluents may contain vaccine antigen. Place bubble wrap or Styrofoam pellets between the refrigerated or frozen coolant packs and the vaccines..

It is important to establish routine, systematic procedures for handling vaccine shipments. Each facility should develop its own written standard operating procedures to address: Receiving Vaccine Shipments. Checking the Condition of a Shipment. Storing and Documenting Vaccine Shipments Upon Arrival. Receiving Vaccine Shipments. Arrange for vaccine deliveries to be made only when the vaccine coordinator or alternate coordinator is on duty. Consider holidays, vacations, staff schedules, and changes in hours of operation when designating vaccine delivery date and time. All staff members (including non-medical staff, e.g., receptionists and other front desk personnel) who accept vaccine deliveries must be aware of the importance of maintaining the vaccine cold chain and the need to immediately notify the vaccine coordinator or alternate coordinator of the arrival of the vaccine shipment so that it can be handled and stored appropriately. Checking the Condition of a Shipment. When you receive your vaccine shipment, it should be examined immediately: Examine the shipping container and its contents for any signs of physical damage. Determine if the shipping time was less than 48 hours (3 days for varicella-containing vaccines). Cross-check the contents with the packing slip to be sure they match. Check the vaccine expiration dates to ensure that you have not received any vaccines or diluents that have already expired or will expire soon. Check that lyophilized (freeze-dried) vaccines have been shipped with the correct type and quantity of diluents for reconstitution. Examine the vaccines and diluents for heat or cold damage. Storing and Documenting Vaccine Shipments Upon Arrival. After the vaccine shipment has been checked according to the procedures described in this section (see Checking the Condition of a Shipment), immediately store the vaccines and diluents at the recommended temperatures and record the arrival of each vaccine and diluent, noting all the details as outlined in the Vaccine Stock Records (see the Vaccine Inventory Management section)..

Each Routine Vaccine Storage and Handling. Plan should include: Up-to-date contact information for: -Primary and alternate vaccine coordinators. -Immunization program (VFC Contact) -Manufacturers of the vaccines. -Refrigerator/freezer maintenance and. repair companies. -Utility/power company. -Vaccine storage unit alarm company. -Sources of packing materials and calibrated. thermometers..

Descriptions of the roles/responsibilities or primary and alternate coordinators. Policy on education and training for staff. Protocols for ordering and accepting vaccine deliveries. Summaries of the storage requirements for each vaccine and diluent. Protocols for vaccine storage unit temperature monitoring. Protocols for vaccine storage equipment maintenance. Protocols for the correct placement of vaccines within storage units..

Protocols for responding to vaccine storage and handling problems. Protocols for vaccine inventory management. Protocols for transporting and receiving shipments. Protocols for handling vaccine prior to administration. Protocols for proper disposal of vaccines and supplies. Samples of the forms used in your vaccination program. Keep your Routine Vaccine Storage and Handling Plan in a prominent and easily accessible location near the vaccine storage unit(s). Also establish a checklist of procedures and post it on all vaccine storage unit(s) (see the IAC link to a Checklist for Safe Vaccine Handling and Storage in the Resources section)..

Immediate Action must be taken to correct improper vaccine storage conditions, including inappropriate exposure to light and exposure to storage temperatures outside the recommended ranges. Actions should be documented and include: Date and Time of occurrence. Ambient room and storage unit temperatures. Description of problem. Action taken. Outcome. Initials of the person documenting the incident. If you become aware of inappropriate vaccine storage conditions (light and/or temperature), the following steps should be taken: Notify the primary or alternate vaccine coordinator immediately of any vaccine storage unit temperature that is outside the recommended range (temperature excursion). If the primary coordinator or alternate coordinator is not available, report the problem to an immediate supervisor. Document the ambient room temperature and the temperature inside the affected storage unit(s) at the time the problem is discovered. Also note minimum and maximum temperature readings in the unit(s). Document the length of time the vaccines may have been exposed to inappropriate storage temperatures or inappropriate light exposure. The temperature information should be available to download from a digital data logger. Conduct an inventory of the vaccines affected by this event and document the actions taken. Note if water bottles were in the refrigerator and frozen coolant packs in the freezer at the time of the event. Label the vaccines DO NOT USE. A clearly labeled paper bag can be used for this purpose. This will reduce risk of inadvertently using vaccines that may have reduced potency because they were stored under inappropriate conditions. Immediately store the vaccines under appropriate conditions separate from other vaccine supplies. If your vaccine storage unit(s) is not maintaining the appropriate storage conditions, activate the Emergency Vaccine Retrieval and Storage Plan (see Storage and Handling Plans). Contact the vaccine manufacturer for further guidance. If you are a VFC provider, please contact the vaccine manufacturer and/or your state/local health department immunization program as directed by the VFC program in your area. Do not discard vaccines unless directed to by your immunization program and/or the manufacturer(s)..

You should have the following in place: Designated primary and alternate coordinator with emergency contact info. Emergency staff contact list in order of contact preference. Vaccine storage unit specifications. Alternate vaccine storage facility or facilities. Written protocols, vehicles and drivers for transporting vaccines to and from the alternate vaccine storage facility. General Guidelines. To protect the vaccine inventory and to minimize potential monetary loss, every facility that stores vaccine should have a written Emergency Vaccine Retrieval and Storage Plan. If a problem is short term (usually 2 hours or less) and depending on ambient room temperature, the storage temperature can probably be maintained with the water containers in the refrigerator, with frozen coolant packs in the freezer, and by keeping the storage unit door(s) closed. Post the Emergency Vaccine Retrieval and Storage Plan on or near the vaccine storage equipment. Ensure that all staff (current, new, and temporary) read the plan and understand it. Also ensure that janitorial and security staff are aware of the plan and know the procedures to follow to notify designated personnel about any problems with the vaccine storage equipment or power outages. Review and update the contact lists in the plan at least quarterly; review and update the entire plan at least annually. When state officials, local officials, or providers have reasonable cause to believe that weather conditions, natural disasters, or other emergencies might disrupt power in or flood any facility where vaccine is stored, emergency procedures should be implemented in advance of the event..

Written instructions for entering your facility and vaccine storage spaces in an emergency if the building is closed. Appropriate packing materials to safely transport or temporarily store vaccine. Written protocol for vaccine packing. Designated primary and alternate vaccine coordinators with emergency contact information. In addition to their routine vaccine storage and handling duties (see the Vaccine Personnel section for details), the primary and alternate vaccine coordinators should: Monitor the operation of the vaccine storage equipment and systems; Track inclement weather conditions; Set up and maintain a monitoring/notification system during times of inclement weather or other conditions that might cause a power outage (a continuous-monitoring temperature alarm/notification system should be considered, especially for facilities with large inventories); Post emergency contact information on circuit breaker(s) or electrical panel; Ensure the appropriate handling of vaccine during a disaster or power outage; Ensure 24-hour access to the building and vaccine storage unit(s); Ensure that sufficient fuel is on hand to continuously run the generator for at least 72 hours if the facility has a back-up generator. Emergency staff contact list in order of contact preference. Determine whether all or certain persons on the list should be contacted in the event of a vaccine storage emergency or if the first person reached is sufficient. Include the primary and alternate vaccine coordinators on the list. Record the names (in order) and contact information. Assure that contact information is kept up to date. Vaccine storage unit specifications. For each vaccine storage unit in your facility, identify the type of unit (e.g., stand-alone refrigerator), the brand name, the model number, and the serial number. These specifications may be useful for the repair company. Alternate vaccine storage facility or facilities. Establish working agreements with at least one alternate storage facility with a back-up generator where vaccines can be appropriately stored and monitored for the interim (e.g., hospital, long-term care facility, state depot, Red Cross, fire station, packing plant, commercial pharmacy). Written protocols, vehicles, and drivers for transporting vaccines to and from the alternate vaccine storage facility. – If the vaccines must be moved to an alternate facility, they may be transported in portable actively or passively cooled refrigerator or freezer units or hard-sided insulated containers. The vaccines may be transported within non-commercial vehicles inside the passenger compartment (not in the trunk because temperatures cannot be controlled inside the trunk). Appropriate packing materials to safely transport or temporarily store vaccine. Vaccine manufacturers do not recommend reuse of shipping materials, including coolant packs and shipping containers, to further transport vaccine products. Written protocol for vaccine packing. Each facility should develop its own standard operating procedures (SOPs) for packing vaccines..

This slide represent the document for Routine and Emergency Vaccine Handling Plan Templates which providers can use as a guideline to follow developing routine and emergency handling plans. They should be posted near your storage unit or where they can be easily accessed in case of an emergency..

Only authorized personnel should have access to the vaccine supply. This will help to protect the vaccine supply by avoiding inappropriate removal of vaccines or inappropriate handling of vaccines and vaccine storage units by untrained personnel. Authorized personnel should be trained to interpret expiration dates, how to handle mishandled vaccines and diluents, transferring vaccines and diluents, rotating stock and documenting vaccine inventory..

Only the primary and alternate vaccine coordinators. Only new staff during orientation. All staff who handle or administer vaccines, including accepting shipments. D) All staff who handle or administer vaccines, including accepting shipments..

Checking that vaccines are potent and effective when used. Maintaining proper storage temperatures at every link in the chain. Minimizing exposure to excessive heat or cold. Checking vaccines for physical evidence of lost potency before administration. B) Maintaining proper storage temperatures at every link in the chain..

vaccine storage unit is not working. correctly. What needs to be taken. immediately Move the vaccines to the staff lounge refrigerator. Notify the vaccine coordinator, alternate coordinator, or supervisor. Throw out all the vaccines in the failed unit. Attempt to fix the unit. Notify the vaccine coordinator, alternate coordinator, or supervisor..

A proper cold chain is a temperature-controlled supply chain that includes all equipment and procedures used in the transport and storage and handling of vaccines from the time of manufacturer to administration of the vaccine. Out of range temperature readings require IMMEDIATE action. For patients to be protected by the vaccines it is your responsibility to handle vaccines with care. Vaccine management, including proper storage and handling procedures, is the basis on which good immunization practices are built. An estimated 17% to 37% of providers expose vaccines to improper storage temperatures, and refrigerator temperatures are more commonly kept too cold than too warm. Colder is NOT BETTER for inactivated vaccines. Out of range temperature readings require IMMEDIATE action. Remember, if you want your patients to be protected by the vaccines you give them, it is your responsibility to handle vaccines with care. Good practices to maintain proper vaccine storage and handling can ensure that the full benefit of immunizations are realized..

Providers should review helpful vaccine management material. available via the following links: CDC’s Vaccine Storage and Handling Home Page CDC’s Storage and Handling Toolkit (Contact your Immunization Program Consultant for a hard copy) You Call the Shots: Vaccine Storage and Handling Module – An interactive, web-based module that provides learning opportunities, self-test practice questions, reference and resource materials, and an extensive glossary.

The Immunization Program webpage contains various helpful information. The webpage address is at the top of the slide..

GA Immunization Program Office. On call Help line: GRITS Help Line: VFC Help Line: Website Your local Immunization Program Consultant (IPC) GA Chapter of the AAP. GA Academy of Family Physicians.

The Storage and In-Use Stability of mRNA Vaccines and Therapeutics

Safety and efficacy of an rAd26 and rAd5 vector-based heterologous

Page 49 Vaccine Storage Images - Free Download on Freepik

IJMS, Free Full-Text

Drug development process PowerPoint templates, Slides and Graphics

Vaccine storage

PPT - Vaccine Storage and Handling PowerPoint Presentation, free

Microsoft's New 'Copilot' AI Can Create a PowerPoint And Even

30 Top Medical PowerPoint Templates (For Amazing PPT Health